Digitalization of the supply chain with our Asian suppliers

China is a major emerging market that can offer STEINEL a comparative competitive advantage in sourcing its required purchased parts, merchandise and services. It is not just economic hurdles that need to be overcome in order to be successful.

The challenge

It takes several trips to China to understand the country, its people and its relentless ambition for growth and progress at least to some extent from a Western perspective.

Not only the language or eating habits are foreign to the Western world, but also mentality, culture, behavior and economic as well as political thinking often leave the outside observer in the dark.

Procurement processes and purchasing activities with Chinese suppliers can therefore also be very extensive, if not extremely costly in terms of TCO. It's about transparency, it's about bridging distances and cultural discrepancies - yes, it's especially about a uniform, simple communication policy, the information of which must be accessible to Steinel and its suppliers and forwarders at all times, understandably, correctly and to the same extent.

The decision

In cooperation with logistics service provider M+R Spedag Group, Steinel called for a joint project back in 2013 to make procurement processes between Steinel's European plants, its Chinese suppliers and logistics partners transparent and efficient. The overriding goal was to evaluate, intervene and avoid potential procurement risks in good time. The focus was always on using a common information platform and standardizing processes.

After successful procurement process analysis and process optimization, the M+R standard product "Order Management System (OMS)" was customized in several joint project steps to the needs of Steinel to a supply chain tool and digitized in various project milestones (originally mainly manual sub-processes).

This decision meant a change not only for internal procurement at Steinel's European sites, but also for the Asian suppliers in particular, for whom it initially meant a considerable adjustment in their usual day-to-day business, order handling and communications. It was therefore important that before the official "Go Live", selected A-suppliers were invited to an exchange and together we were able to align the system in such a way that it meets our requirements on the one hand and offers a benefit for the suppliers on the other. Only afterwards, and after system test runs, were all suppliers in eastern and southern China invited to workshop seminars, where the new joint cooperation basis was presented and finally went live.

The result

By implementing the IT-based supply chain management system in the procurement process between Asia and Europe, it was not only possible to achieve a significant increase in efficiency and streamlining of the ordering process. A communication and joint working platform was created. On this platform, the entire procurement process is systematically digitalized along defined guidelines (from the creation of the order to the confirmation of delivery at the destination by the forwarder in Europe). By defining these guidelines for Asian suppliers (e.g., for the creation of the invoice and delivery bill) and the connected forwarding agents, the clarification of possible errors and sometimes tedious discussions have been almost completely eliminated. The following project milestones, among others, were gradually digitized in the process:

- Quantity Contract and PO Management

- PO Acknowledgment

- E-booking

- PO and Consignment Tracking

- Document creation (e.g. Commercial Invoice and Packing List)

- Production Status Update

- Event Notifications and Reportings

- etc.

Furthermore we are able to measure the performance of the Asian suppliers permanently. Evaluating past performance indicators is one thing, but the crucial thing is that so-called PPI's (Predicted Performance Indicators) help to identify potential problems in time (i.e. already at the supplier in Asia), e.g. in meeting the delivery date and quality requirements. This is done with the aim of supplying the European Steinel sites and, in particular, our customers on time and in the right quality ("Solve today the problem in Asia that could become a problem in x weeks at the destination in Europe").

So far, this has contributed to measurable success. Above all, the delivery rate could be almost doubled to now almost 96% and a reject rate from almost 20% in 2012 to <1% in the meantime.

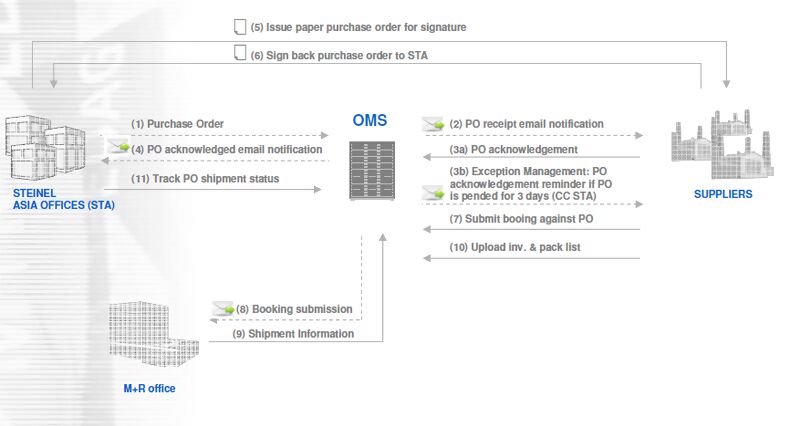

Figure 1 Section of the Process Flow OMS

The conclusion

Heiko Hartkamp, former Head of Procurement, STEINEL Solutions AG

Benno Hägler, Head of Sales Switzerland, M+R Spedag Group AG

"The OMS is a groundbreaking and forward-looking tool. Its capabilities go far beyond purchase order management. It brings together in one web-based platform all the tools for an efficient, effective and transparent supply chain."